Mochine oa mochini oa ho etsa tart ea mahe

Lintlha tsa Sehlahisoa

Mohala oohle o etselitsoe ho theha maemo a bonolo, phetoho e potlakileng ea sehlahisoa, ts'ebetso e bonolo le ho hloekisa.Lihlahisoa li ka ba

e entsoe ka lifoile tse fapaneng, lijana tsa pampiri, literei tsa ho baka tsa tšepe, lihupu, lithini hammoho le literei tsa ho baka tse kentsoeng ka hare.Ka mohlala:

• Lihlooho tse thibelang le tse hlabang li ka fapanyetsanoa ka lehlakoreng la motho a le mong (4 & 8).

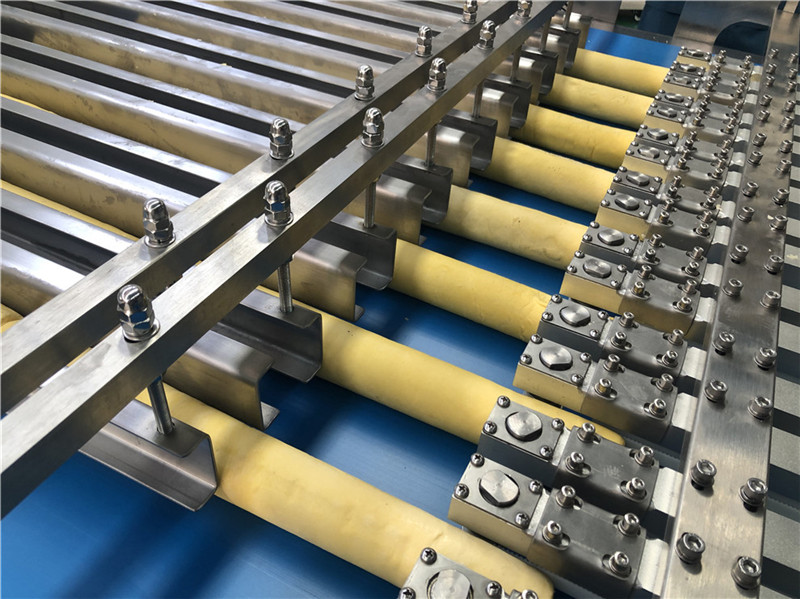

• Sebaka se ka tlas'a conveyor ka kakaretso ke 250,500,800 mm, se nolofalletsang phihlello e ntle bakeng sa tlhoekiso.

• Li-unit tse amehang li na le mabili (4.6.8).

• Mokhoa oa ho futhumatsa oa ho futhumatsa metsi ka Punching.Mocheso oa mocheso o pakeng tsa 48-52 ℃ ± 1 oo ho ea ka mongobo oa hlama ea pastry.

• Mohala o ka hlomelloa ka li-feeders tse fapaneng ho latela bophara bo fapaneng ba pastry roller.

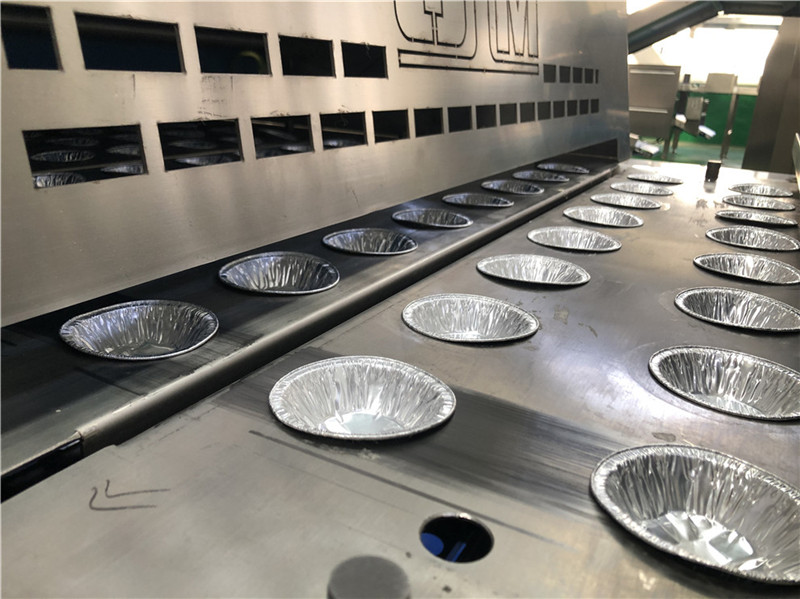

• Ka mor'a ho qhaqha, Egg tart billet e ka hlophisoa holim'a terei kapa ea fetisa ka ho toba e leqhoa.

Bokhoni

•Bophahamo ba pie line bo fapana ho ea ka boholo,

• Diameter 40 mm ho fihlela ho 20.000 likotoana / hora

• Diameter 260 mm ho fihlela ho 5.200 likotoana / hora

•Bolelele ba mohala o qala ho limithara tse 10.5

•Sehlahisoa bophara 40 ho 260 limilimithara

•Bophara ba ho sebetsa 600 - 1200 mm

•Bolelele ba ho sebetsa 850 mm

Tlhaloso ea Sehlahisoa

| Boholo ba mochini(L*W) | 18(L)*2(W)*1.85(H) |

| Bophahamo ba ho sebetsa | 850 limilimithara |

| Bophara ba ho sebetsa | 600-1200 limilimithara |

| Sehlahisoa sa bophara ba mefuta | 40-260 limilimithara |

| Mola | 4-6-8 |

Lintlha tsa mochini li bonts'a

The foil denester e na le vacuum system ho netefatsa hore foil e behiloe ka nepo.

Ho lokisa hlama: UIM Strip feeder

The guillotine netefatsa boima ba hlama e nepahetseng haholo.le Precise product drop position

Li-billet tsa hlama li koetsoe ho sebopeho se lakatsehang ntle le sekhechana leha e le sefe ka mochine oa khatiso oa servo.Hlooho e thibelang ke metsi a futhumetseng bakeng sa ts'ebetso e nepahetseng le e ka tšeptjoang.

Sistimi e fepelang e fetisetsa liphae ho tloha ho conveyor ho ea ho liphanele tse inehetseng empa hape li ka tsamaisoa ka setup bakeng sa ho theoloa ho band ea ontong, infeed ea sehatsetsi kapa literei.